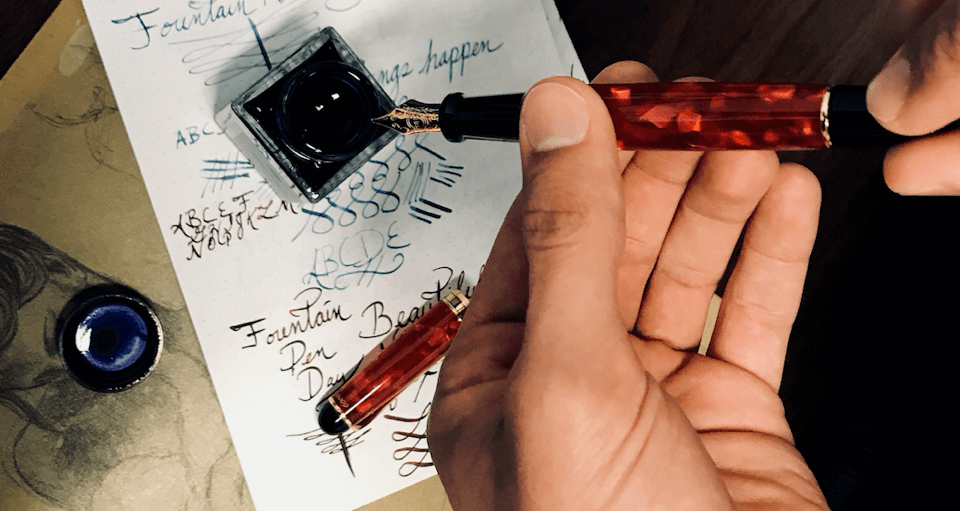

Today we would like to share the process for assembling and testing the piston system on the new Aurora Marte. The Marte has an 88 silhouette and shares the same fountain pen piston system as other Aurora 88 and Optima pens. Aurora goes the extra mile to ensure each pen is ready to be inked and today we provide an example with the steps for their piston assembly process.

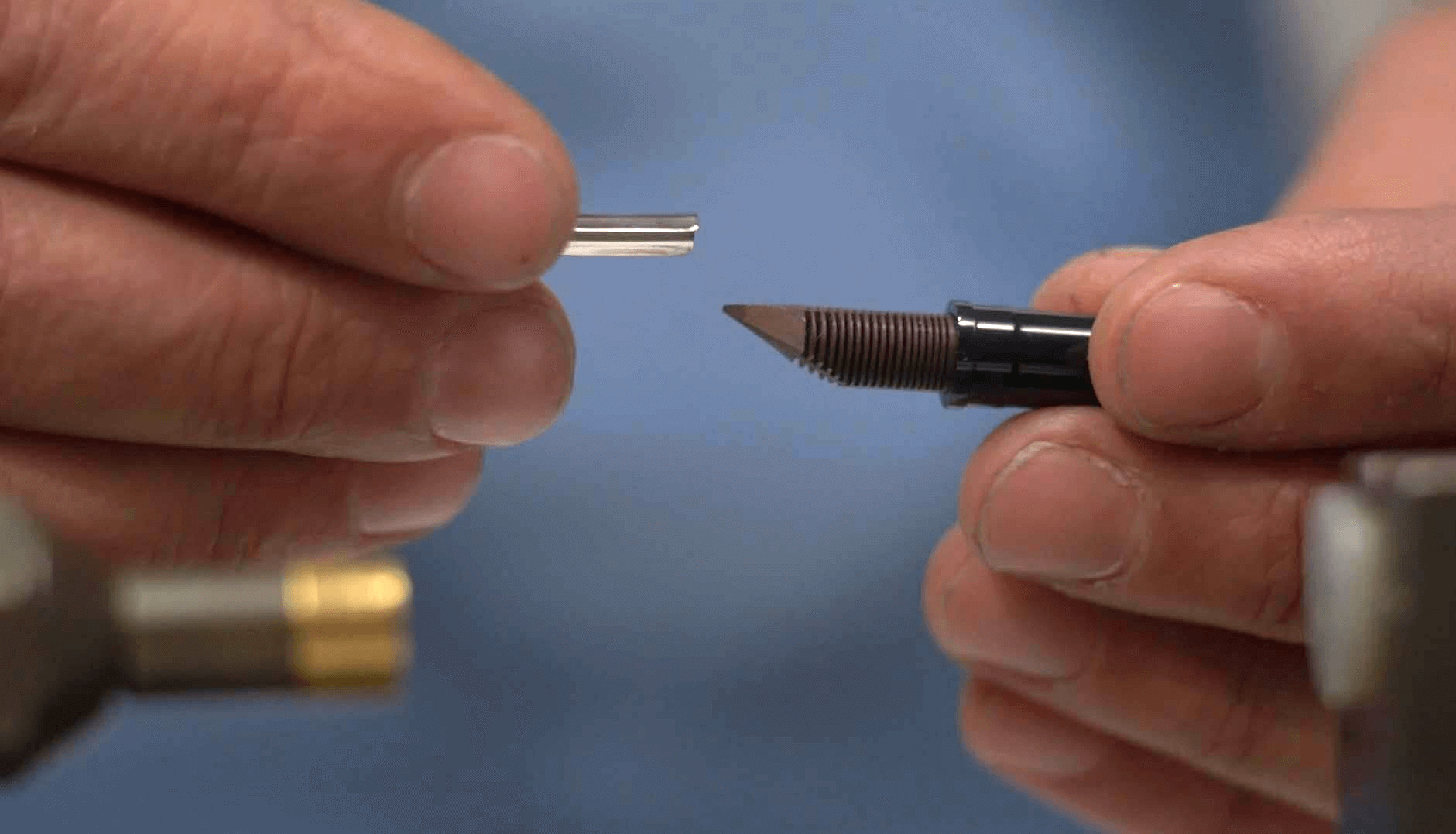

The piston stem and soft rubber seal is manufactured and ready to be applied or inserted to the pen body. However, before the stem can be inserted, there are a few steps that are required.

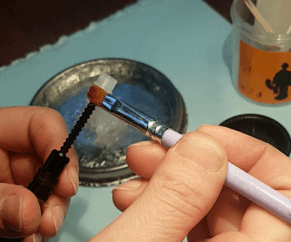

First the seal which slides up and down to create a vacuum for ink must be lubricated to ensure a smooth draw. The Aurora piston functions when the end knob is rotated right or left and the seal slides up and down to create a syringe like system. The knob is rotated counter clockwise to push air out and clockwise to draw in. the seal has been manufactured perfectly to fit the inside of the barrel and therefore a touch of lubrication creates a smooth performance.

The next step in the piston assembly is the sealant application. The Aurora piston is applied and threaded to the barrel. In order to prevent ink leakage, the service team applies a silicone sealant to ensure an air tight seal.

Most companies would be satisfied at this point, but not Aurora. The next step is labor intensive, but one that affirms the Aurora quality standards. Every Aurora fountain pen piston is tested with pressurized air. They have developed a system where they can apply pens to a nozzle, force air and drop in water to check for bubbles. If they see bubbles, then the sealant process must be applied again.

Below you will see photos and short video clips from the factory that show how each step is applied. There is a reason why Aurora manufactures some of the best quality fountain pens and the piston assembly is just one.

See our short video clips below..